Background

Overview

Our client, a leading manufacturing enterprise, operates multiple warehouses in different regions. In the past, inventory management was handled manually — warehouse staff recorded pallet box quantities and types by hand, leading to slow processes, high error rates, and isolated data between locations.

Vi LiDAR Technology provided a 3D vision-based Intelligent Pallet Box Counting System to automate counting, classification, and inventory synchronization across all warehouses.

Industry Challenges

Before Implementation

- Low Efficiency – Manual counting slowed down inbound/outbound processes.

- High Error Rate – Frequent discrepancies between recorded and actual inventory.

- Information Silos – Independent warehouse operations without data integration.

- Lack of Real-Time Tracking – Delayed visibility of stock levels for decision-making.

Our Solution

Technology Highlights

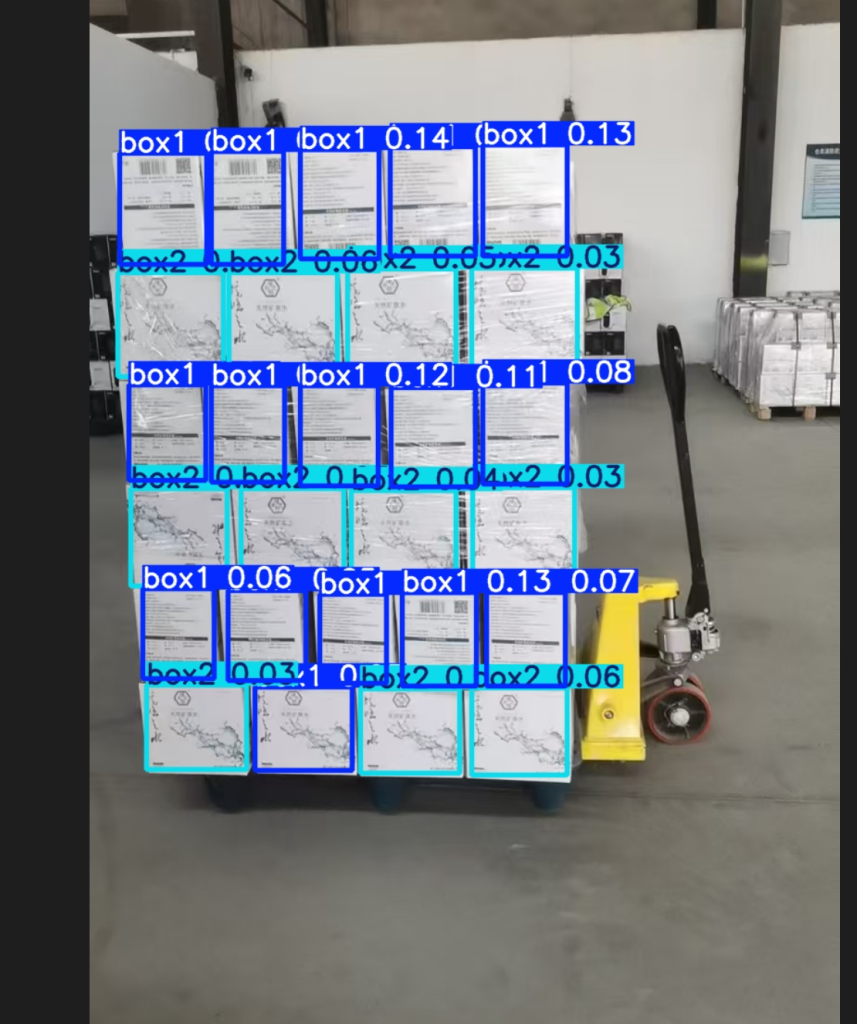

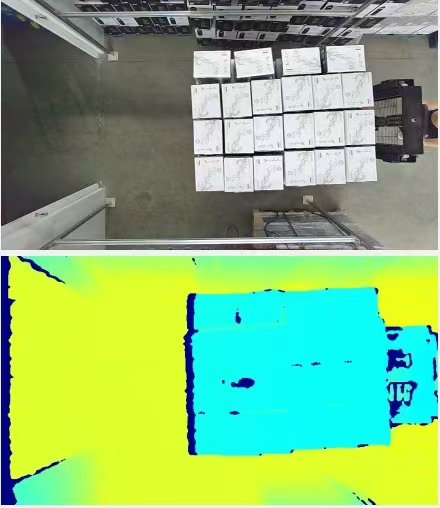

- 3D Vision Detection – When forklifts transport pallets through the detection area, high-resolution 3D cameras scan and detect every box.

- AI-Based Recognition – The system identifies whether pallets are entering or leaving the warehouse.

- Box Type Classification – Automatically recognizes box types for precise categorization.

- Centralized Data Platform – Real-time inventory updates across all warehouse locations, breaking data silos.

Results

| Metric | Before | After Implementation |

|---|---|---|

| Counting Accuracy | ~90% | >98% |

| Processing Efficiency | Baseline | +40% |

| Data Synchronization | Manual, delayed | Real-time |

| Inventory Visibility | Limited | Full, cross-location |

Key Benefits

- Reduced labor workload and human error.

- Faster inbound/outbound processes.

- Unified and accurate stock data for production planning and logistics.

Customer Feedback

“The Vi LiDAR Technology system has completely transformed our warehouse operations. The automation not only improved efficiency but also gave us a clear, unified view of inventory across all locations. This is a game-changer for our business.”