Transforming Manual Sampling with 3D Vision

In large-scale grain and feed processing plants, truck sampling automation has become essential for improving accuracy, efficiency, and safety. Traditionally, quality inspection relies on manual sampling, where each truck must be inspected within seven minutes. However, manual measurement of truck profiles is prone to errors—affected by lighting, uneven ground, and operator judgment—resulting in delays and inconsistent data.

Vi LiDAR Technology addresses these challenges by introducing a 3D vision–based truck profile measurement system, enabling truly automated truck sampling across different vehicle types and loading conditions.

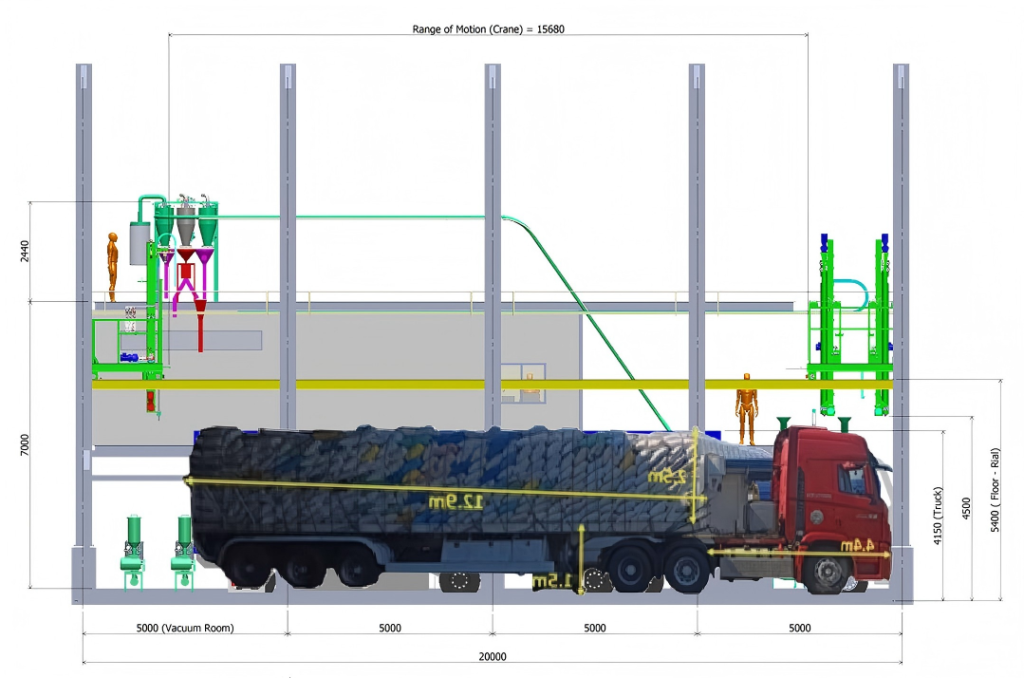

Intelligent 3D Vision System for Truck Sampling Automation

Vi LiDAR’s system integrates dual 3D LiDAR sensors and AI-driven algorithms to deliver precise, real-time data for truck body and material volume measurement.

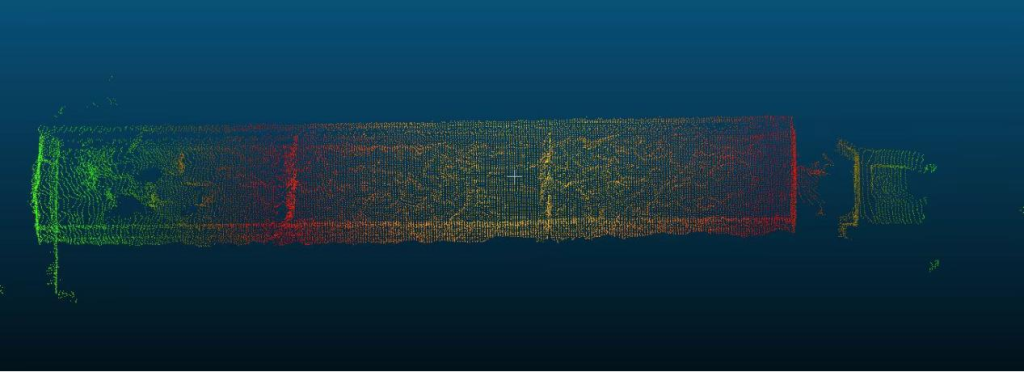

- 3D Truck Profile Measurement

Using high-frequency laser scanning, the system reconstructs the truck’s full 3D contour—including sideboards, bottom height, and load surface—ensuring complete coverage without blind spots. - Dual-LiDAR Architecture

Two LiDAR units are mounted longitudinally to capture the entire truck length (up to 18 meters) with millimeter-level accuracy, enabling automated calculation of sampling positions and material volume. - Side Calibration for Height Accuracy

A lateral LiDAR continuously calibrates side and base heights, maintaining precise measurements even in dusty or uneven environments. - Smart Vehicle Recognition

Deep learning enables automatic detection of truck types and internal configurations, ensuring reliable data for volume analysis and quality inspection.

Key Advantages of Vi LiDAR’s Automated Truck Sampling Solution

- High-Precision Spatial Digitization

The system synchronizes two LiDAR units to build a complete 3D digital model of the truck bed, generating accurate parameters for automated sampling and inspection. - All-in-One Design for Rapid Deployment

The compact integration of sensors and processors reduces installation complexity and hardware costs while completing data acquisition and analysis within minutes. - Adaptability to Fully Loaded Trucks

The side-mounted LiDAR eliminates height blind spots and ensures stable performance across different materials and reflectivity conditions.

Proven Success in Feed Industry Applications

Deployed by a leading feed manufacturer, Vi LiDAR’s 3D vision–powered truck sampling automation system has delivered measurable results:

- Reduced inspection time below seven minutes

- Eliminated manual measurement errors and safety risks

- Enabled instant vehicle verification with RFID integration

- Supported diverse truck types with automated 3D profiling

- Lowered maintenance and operation costs through simplified design

- Improved material quality control and traceability

Driving the Future of Intelligent Sampling

With its deep expertise in 3D vision and LiDAR fusion, Vi LiDAR Technology empowers industrial customers to transition from manual inspection to data-driven, automated operations.

The system not only enhances truck profile measurement accuracy but also integrates seamlessly into digital quality management systems—creating a closed-loop workflow from data acquisition to decision-making.

By combining perception, analysis, and control, Vi LiDAR Technology continues to lead the automation of truck sampling, making intelligent quality inspection faster, safer, and smarter.