In industries such as mining, aggregates, cement, coal, ports, and construction, accurate volume measurement of stockpiles is a fundamental aspect of inventory management, operational scheduling, and financial accounting. This article compares three mainstream volumetric measurement technology solutions: fixed LiDAR systems, drone scanning systems, and handheld SLAM scanning systems. It provides an in-depth analysis from the perspectives of working principles, advantages, limitations, and applicable scenarios, helping enterprises select the most suitable intelligent volumetric measurement solution tailored to their on-site conditions.

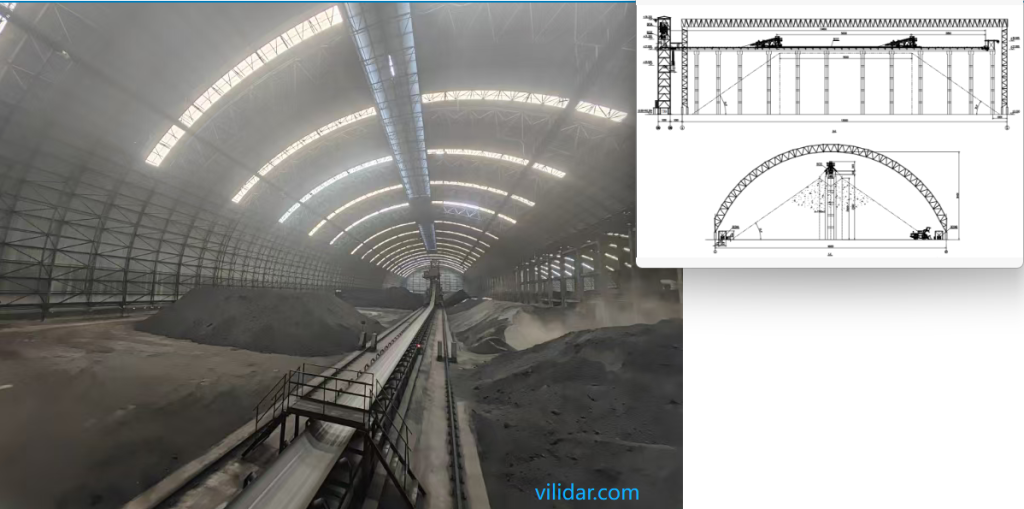

Solution 1: Fixed LiDAR-based Volume Measurement System (Typical Solution from Vi-LiDAR Technology )

✅ Principle

Mounted at a high position — such as on masts, material shed roofs, or gantry cranes — the 3D LiDAR sensor performs continuous rotary scanning over the stockpile area to capture high-density 3D point cloud data. The system automatically reconstructs the ground surface and material topography within an edge computing unit. By integrating predefined zone segmentation and material density parameters, it calculates the volume and weight of each sub-region in real time, and stores the results in a database for further management and analysis.

Core Advantages

- Scheduled or Remote Scanning:Supports daily automatic scanning according to preset schedules, and also allows manual remote activation via the backend system for on-demand measurement.

- Customized Zone Management:Enables custom numbering and material type assignment for each stockpile area. Automatically generates zoned statistical reports for clear inventory and operational insights.

⚠️ Limitations

- Initial deployment requires structural installation and setup, which may involve time and effort.

- Not suitable for temporary or small-scale stockpile sites.

- If the installation location is changed, recalibration of the system will be required to ensure measurement accuracy.

✅ Applicable Scenarios

Ideal for large-scale material yards, permanent material sheds, aggregate distribution warehouses, coal trading centers, mining sites, and port stockpiles where consistent, high-volume, and high-accuracy volume measurement is required.

___________________________________________________________________

Solution 2: UAV-Based Volume Scanning System (Drone LiDAR or Photogrammetry)

✅ Principle

The UAV is equipped with either a LiDAR sensor or a high-resolution camera to perform aerial scanning over the stockpile. A 3D model of the material pile is reconstructed using Structure-from-Motion (SfM) photogrammetry techniques or lightweight LiDAR SLAM (Simultaneous Localization and Mapping)algorithms. By referencing a base ground plane and applying known material density values, the system calculates the volume of the stockpile.

Core Advantages

- Flexible & Mobile:Suitable for irregular, temporary stockpiles or locations where fixed radar installation is impractical.

- Wide & Rapid Coverage:A single flight can capture data over areas of tens of thousands of square meters.

- Quick Deployment:No construction or infrastructure required, ideal for short-term projects or newly established stockyards.

⚠️ Limitations

- Limited Flight Endurance:Typical flight time is around 20–30 minutes per battery, requiring frequent battery swaps for extended operations.

- Lengthy Data Processing Workflow:After scanning, data must be manually exported, transferred to a computer, and processed for modeling and analysis — results are not available in real time.

- Variable Accuracy:Measurement accuracy can be affected by flight altitude, lighting conditions, and the presence of obstructions.

- Flight Restriction Zones:Usage is limited or prohibited in no-fly zones such as near airports or inside enclosed spaces like coal sheds.

✅ Applicable Scenarios

Suitable for medium to large temporary stockyards, open-air ore or aggregate (sand and gravel) stockpiles, construction-phase storage sites, and waste material inventory or clearance operations.

_______________________________________________________________________________________________

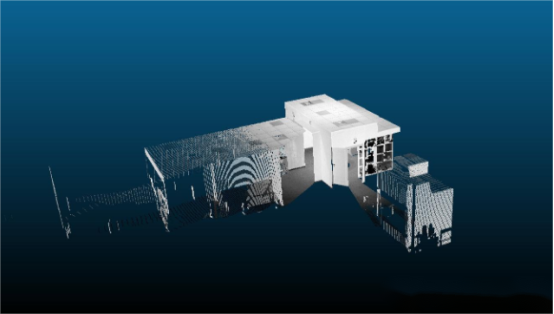

Solution 3: Handheld SLAM Scanning System

✅ Principle

The device integrates a 3D LiDAR sensor and an IMU (Inertial Measurement Unit), and utilizes SLAM (Simultaneous Localization and Mapping) algorithms to generate a point cloud map as the operator walks and scans around or above the stockpile. Volume calculation is performed by referencing a calibrated base plane and applying known material density.

Core Advantages

- Easy Deployment:No installation required. Simply walk around or on top of the pile with the handheld device to perform scanning.

- Low Cost:Lower initial investment compared to drones or fixed LiDAR systems.

- High Adaptability:Can be used in enclosed, confined, or complex environments where other systems are impractical.

⚠️ Limitations

- Accuracy Depends on Scanning Path & SLAM Stability:Measurement precision is influenced by the operator’s walking route and the robustness of the SLAM algorithm.

- Not Automated:Data must be manually imported into a computer for modeling and analysis — no real-time output.

- Higher Operator Skill Required:Requires steady and logical walking paths to ensure good mapping quality; not beginner-friendly.

- Not Suitable for Large Areas:Inefficient for large-scale stockpiles; better suited for small-area or detailed inspections.

✅ Applicable Scenarios

Ideal for trial section measurements, small stockpiles inside warehouses, tunnel material accumulations, gap-filling surveys, and other small-scale or hard-to-reach areas that require fine-detail volume assessment.

_________________________________________________________________________________________________________________________________________

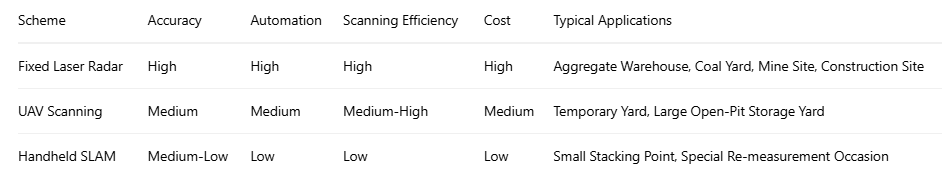

Comparison Summary

✅ Recommended Solution by Vi-LiDAR Technology

Vi-LiDAR Technology in-house developed fixed 3D LiDAR volume measurement system has been widely applied in scenarios such as sand & aggregate yards, concrete aggregate silos, mineral stockpiles, and coal trading centers. The system offers multiple advanced features, including:

- Automated scanning

- Zoned segmentation & statistical reporting

- Data visualization

- Remote system management

It also supports seamless integration with ERP systems, enabling efficient digital management and business process connectivity.