Industry Pain Points: Challenges in Conveyor Belt Material Measurement (LiDAR Volume Measurement System)

In industries such as mining, steel, and cement, the transportation and measurement of bulk materials are critical to production management. However, many enterprises still face the following challenges:

- Inaccurate Measurement: Traditional methods, such as manual visual estimation or weight sensors, often introduce errors, affecting production planning.

- High Reliance on Manual Labor: Dedicated personnel are required for monitoring, increasing operational costs.

- Lack of Traceable Data: Real-time recording of material transportation data is difficult, impacting production scheduling.

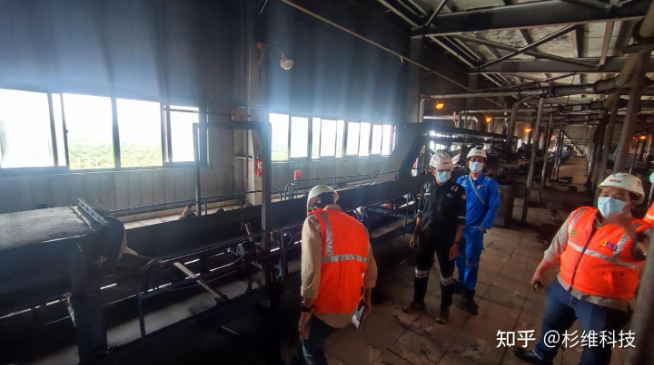

In the global energy sector, coal-fired power plants play a vital role in power supply. However, coal transportation in these plants often faces challenges such as inaccurate material measurement and high labor costs. To address these issues, PT PLN (Persero) Indonesia, the national electricity company, partnered with Shanwei Technology to successfully implement a belt conveyor volume measurement system. This solution significantly improved the efficiency and accuracy of coal transportation .

_____________________________________________________________________________________________

Project Background

As the primary electricity provider in Indonesia, PLN operates coal-fired power plants that handle large volumes of coal daily. However, traditional measurement methods used in coal transportation suffer from inaccurate readings and poor real-time performance , leading to reduced production efficiency and increased operational costs .

Challenges

- Inaccurate Measurement: Traditional weight sensors and manual visual estimation are susceptible to environmental factors, resulting in significant data discrepancies.

- High Labor Costs: Requires dedicated personnel for monitoring, increasing human resource allocation.

- Data Lag: Inability to obtain real-time material conveyance data impacts production scheduling and decision-making.

Solution ( LiDAR Volume Measurement System )

To address these challenges, Vi-LiDAR Technology provided PLN with a belt conveyor volume measurement system based on LiDAR technology. This system employs high-precision LiDAR to perform real-time scanning of coal on the conveyor belt. By integrating AI algorithms , it accurately calculates material volume and transmits data in real time to the control center.

Implementation Results

- Improved Measurement Accuracy: ( Lidar sensor) The system maintains a measurement error within ±2%, ensuring high data reliability.

- Reduced Labor Costs: ( Lidar scanner ) Achieves unmanned monitoring, decreasing reliance on manual labor and lowering operational expenses.

- Real-Time Data Monitoring: Management can monitor material conveyance in real time , optimizing production scheduling and enhancing overall operational efficiency.

Customer Feedback

PLN reported that Vi-LiDar Technology’s belt conveyor volume measurement system effectively resolved their challenges in coal transportation, including inaccurate measurements and high labor costs. The system has boosted production efficiency, reduced operational expenses, and delivered significant economic benefits to the enterprise. Through this collaboration, Vi-LiDar Technology demonstrated its technical expertise in industrial material measurement, providing a reliable solution for large-scale industrial facilities like coal-fired power plants. This helps businesses achieve smarter, more precise management and advance toward intelligent operations ( 3D Lidar volume measurement).