Vi-LiDAR

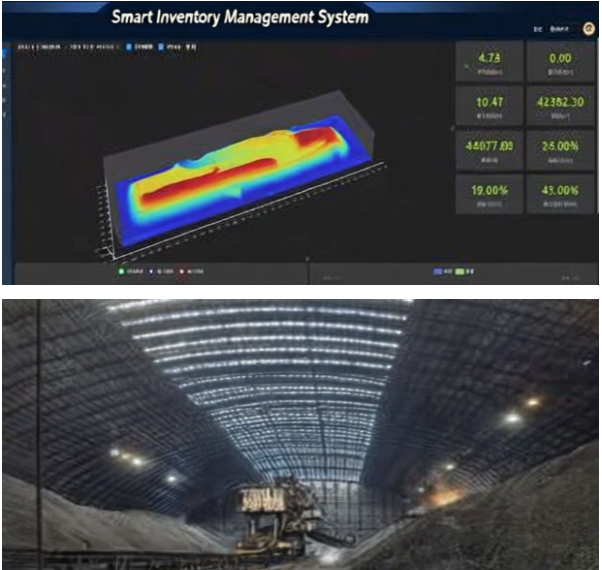

Recently, we successfully completed the intelligent measurement project at a large coal yard. The core solution integrated 6 CP-L260 lidar scanners with dynamic conveying devices, enabling efficient and precise measurement of multi-form material piles—establishing a technical benchmark for “real – time monitoring and accurate control” in coal storage.

Ⅰ. Project Background: Traditional Pains in Yard Management

Coal yards generally face three major challenges:

- Complex Structure: Multiple stacks with large height differences are hard to cover using manual labor or single – sensor methods.

- Diverse Materials: Different coal types have varying densities and reflection properties, leading to fluctuations in measurement accuracy.

- Environmental Interference: Frequent dust and light changes reduce the stability of traditional equipment.

Traditional manual inventory and single – sensor solutions can no longer meet the “high – frequency, high – precision, real – time” requirements, making intelligent upgrading an urgent need.

Ⅱ. LiDAR scanners CP – L260 Lidar: Technical Parameters Define “Measurement Confidence”

The LiDAR Scanners “CP – L260”, the core device of this project, adapts to complex scenarios with its strong parameters:

- Light Source & Frequency: With a 905nm laser light source (an eye – safe band) and a 452 kHz emission frequency, it ensures “fast and stable” data collection.

- Field of View & Scanning: A 120°×180° ultra – wide field of view covers multi – yard areas, and a 10Hz scanning frequency enables “real – time modeling” of dynamic scenes.

- Range & Accuracy: It can detect up to 260m@90% reflectivity (150m@10% reflectivity), and the false alarm rate is as low as 0.01%, guaranteeing data reliability in dusty environments.

Ⅲ. Solution Design: “Multi – Lidar + Dynamic Conveying” Synergy for Breakthroughs

Considering the “multiple stacks running in parallel + dynamic loading and unloading” characteristics of the yard, the project adopted a network of 6 CP – L260s + dynamic conveying device linkage solution:

- Multi – dimensional Scanning: 6 LiDAR Scanners from different directions. Algorithms integrate the data to generate 3D point cloud models, accurately restoring pile contours and volumes.

- Dynamic Response: The conveying link captures pile deformation in real – time during loading and unloading, ensuring the “timeliness” and “accuracy” of measurement data.

IV. Value Delivery: From “Extensive” to “Precise” Transformation

After the project delivery, the yard achieved three major upgrades:

- Efficiency: The time for a single full – yard measurement was reduced to one – third of the traditional method, supporting “multiple inventories per day”.

- Precision: The material volume error is ≤ ±1%, providing a reliable basis for inventory accounting and cost control.

- Reusability: The technical solution can be extended to bulk commodity yards such as ores and sands, facilitating the intelligent transformation of bulk storage.

Continuous technological iteration reshapes industries. The practice of the LiDAR Scanners CP – L260 in the coal yard is a successful verification of “lidar + algorithm + scenario”. In the future, we will continue to deepen research and development in the bulk commodity field and solve more industry challenges through technological innovation.