——LiDAR + AI Fusion Solution Improves Inventory Accuracy, Operational Safety, and Dust-Resilient Monitoring

🟩 Client Background: Challenges in Stockpile Management at El Abra Copper Mine

Sociedad Contractual Minera El Abra, one of the major copper mining operations in Chile, faced three critical challenges in its coarse ore stockpile yard:

- Blind Spots in Inventory Management: No real-time data on stockpile volume, causing frequent downstream production halts due to material shortages.

- Bulldozer Safety Risks: Machines repeatedly fell into material voids near chutes due to poor terrain awareness, with each incident costing tens of thousands of dollars.

- Dust-Constrained Monitoring: Manual inspection was inefficient and unsafe; conventional sensors often failed in heavy dust conditions.

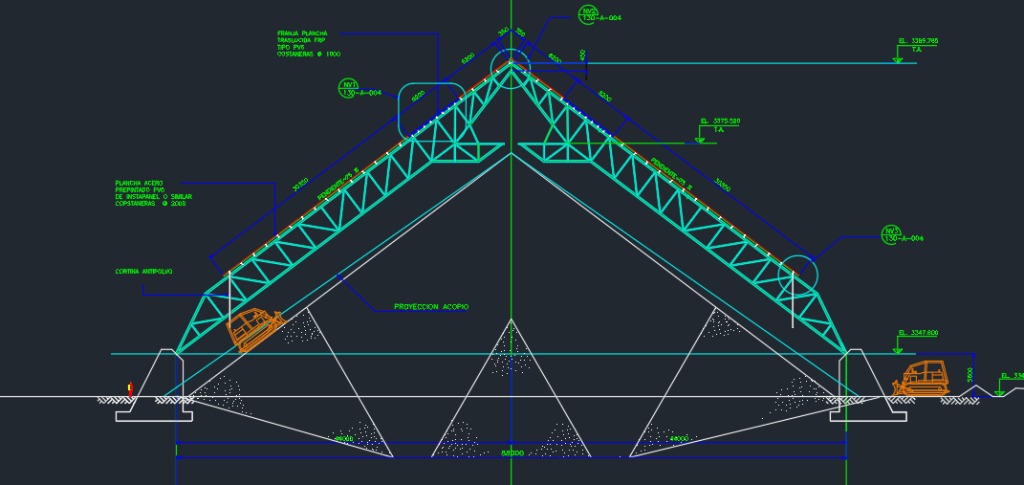

Vi LiDAR’s 3D Stockpile Monitoring and Perimeter Safety System

To address these issues, Vi LiDAR implemented its proprietary “3D Dynamic Stockpile Monitoring & Perimeter Safety Warning System”, integrating three core technology modules:

🔷 1. Millimeter-Accurate Stockpile Volume Measurement

- Multi-Sensor Fusion Modeling:

Six high-precision LiDARs and thermal cameras scan the entire stockpile yard every 30 seconds, continuously updating a full 3D point cloud model. - Real-Time Inventory Visualization:

The system calculates real-time stockpile volumes with ≤1.5% error, displaying dynamic inventory curves and alert thresholds on the central dashboard. - Smart Replenishment Decision-Making:

Connected with the production management system, the solution triggers automatic refill tasks when stock levels fall below safety limits, cutting idle time by 92%.

🔷 2. Bulldozer Operational Safety with Dual-Layer Protection

- Positioning + Terrain Awareness:

Using UWB and RTK dual-location tracking, bulldozers are monitored in real-time and their positions mapped against the 3D chute terrain. - Dynamic Virtual Fencing:

A 5-meter virtual safety zone is created around the chute; approaching vehicles trigger audible/visual alerts and notifications in the control room. - Historic Route Replay:

Bulldozer travel paths are logged for safety audits and optimized route planning—zero incidents have occurred since deployment.

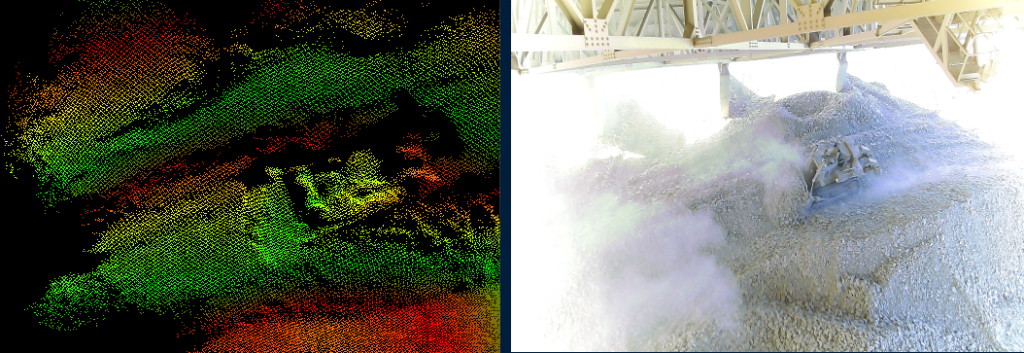

🔷 3. Perimeter Security Under Dust-Intensive Conditions

- Dust-Penetrating AI Algorithms:

LiDAR scans continue working in low visibility, and AI filters out noise from the environment with 99.3% accuracy in detecting intrusions. - Multi-Level Alerting System:

Intrusions by people or vehicles in restricted zones trigger alarms across beacons, in-vehicle tablets, and central monitoring panels. - Unmanned Patrol Replacement:

Manual patrol frequency reduced by 85%, saving approximately $120,000/year in labor costs.

Performance Highlights: Operational Efficiency & Safety Upgrades

✅ Inventory visibility improved to minute-level precision, reducing downstream idle rate to below 3%

✅ Zero bulldozer fall-in incidents; monthly downtime loss cut by $250,000+

✅ Maintenance and patrol costs reduced by over $186,000 annually

“We now have real-time visibility into every inch of the yard from our control room. Efficiency and safety have reached their highest levels in a decade.”

— Operations Director, El Abra Copper Mine