Customer Background

Our client is a state-owned enterprise in China, specializing in grinding raw ores into fine particles for use as construction materials such as sand and gravel. These materials are stored in a semi-open stockpile yard, posing challenges in inventory visibility and real-time material tracking.

Challenges

🔹 Inventory estimation relied heavily on experience

Seasoned sales staff could estimate stock levels by interpreting camera footage. However, new team members lacked this intuition, leading to frequent delays in processing orders due to inventory uncertainty.

🔹 Lack of traceability in material inflow and outflow

Without automated measurement tools, the finance department struggled to track material movements, resulting in inaccurate or missing warehouse records.

🔹 Material loss in open-yard environments

The open nature of the stockpile yard made materials susceptible to environmental factors like wind and rain, resulting in undetected losses and security risks.

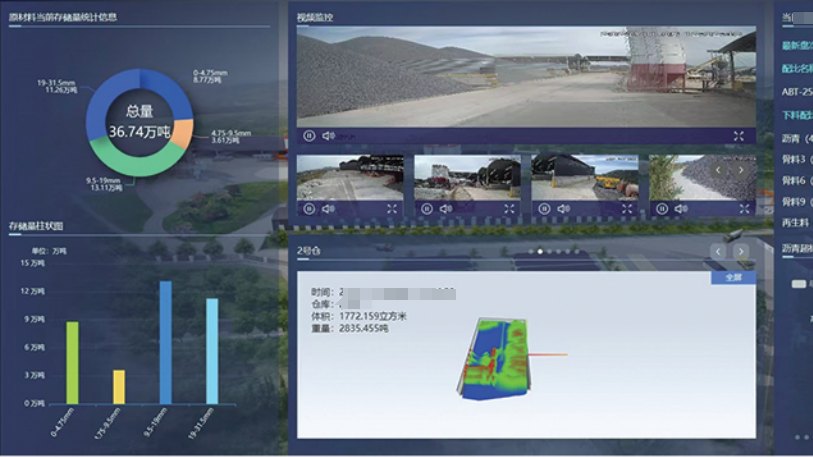

ViLiDAR Solution: 2D LiDAR + PTZ Integration for Smart Stockpile Monitoring

To address these challenges, Sunway Technology (ViLiDAR) deployed a smart volume measurement system powered by proprietary 2D LiDAR sensors mounted on a high-precision pan-tilt unit.

Key Highlights

⚙️ Plug-and-Play Industrial Hardware, Designed for Mobility

Mining sites typically relocate every 2–3 years, and warehouse layouts shift accordingly. ViLiDAR’s hardware features an all-in-one industrial design—simply plug in power and Ethernet to get started, making it ideal for mobile deployments.

🧠 Modular Software with Visual UI – No Coding Required

The system uses a modular, visual programming interface, allowing users to independently configure zones, warning thresholds, and measurement parameters—no programming experience needed.

📏 Multi-Zone Volume Measurement with Custom Mapping

Customers can define separate areas for different materials (e.g., sand, aggregate, soil). The system then generates real-time point cloud data and calculates individual volume metrics per zone, providing clear and actionable inventory insights.

Project Outcomes

✅ Faster, Smarter Sales Operations

Real-time inventory visibility helps the sales team process orders efficiently, minimizing delivery delays.

✅ Accurate Finance & Material Tracking

Daily reports capture material inflow/outflow, enabling precise reconciliation and stock auditing.

✅ Improved Material Security & Operational Safety

The system integrates with security alerts. If foreign objects enter restricted zones, audible and visual alarms are triggered, with alerts sent to the control room.

Client Testimonial

“Before ViLiDAR, we were relying on guesswork. Now we know exactly how much material we have—instantly. This has transformed the way we manage inventory and respond to orders.”

— Mr. Wang, Sales Manager, State-Owned Mining Company