📝Summary

In the grain storage industry, accurate volume measurement is crucial for managing inventory and calculating costs. Traditional manual measurement methods are not only time-consuming but also prone to errors, which can result in inaccurate stock levels and financial discrepancies. VI LiDAR’s 3D volume measurement system helps solve these issues by offering automated, accurate, and fast parcel volume measurement with minimal human intervention. This system increases throughput, reduces manual labor, and improves accuracy in grain silo operations.

💬 Client Testimonial

“We handle thousands of tons of grain daily, and precise volume measurement is critical for inventory management and cost calculations. Since adopting VI LiDAR’s automated 3D volume measurement system, we’ve greatly enhanced our operational efficiency and ensured more accurate measurements, leading to fewer inventory discrepancies and better financial forecasting.”

— Operations Manager, Penny Zhou

📉 Challenges in Traditional Grain Volume Measurement

Manual Measurement Limitations

Traditional methods often involve manual sampling and estimation, leading to:

- Inaccuracy: Human errors can result in significant discrepancies.

- Labor Intensity: Regular manual checks require substantial manpower.

- Operational Disruption: Manual processes can interfere with regular silo operations.

Impact on Inventory and Quality Control

Inaccurate measurements can lead to:

- Inventory Discrepancies: Challenges in tracking stock levels accurately.

- Quality Assurance Issues: Difficulty in maintaining consistent grain quality.

🧠 Automated Measurement Solutions: Leveraging Advanced Technologies

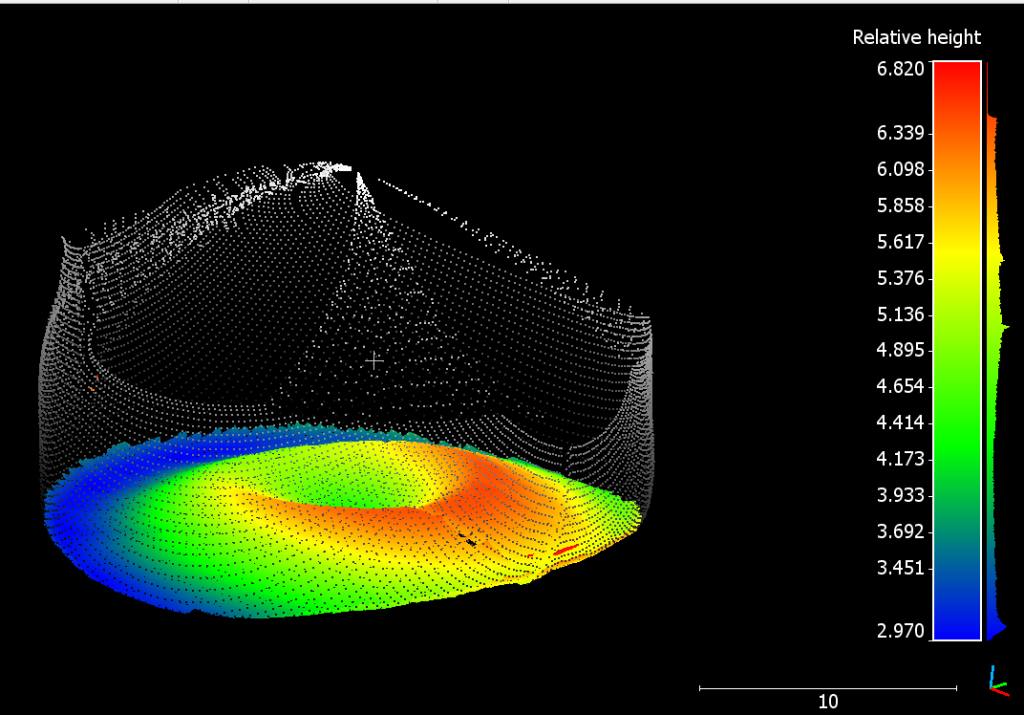

3D LiDAR Scanning Technology

Implementing 3D LiDAR scanning offers:

- High Precision: Accurate volume measurements with minimal error margins.

- Non-Intrusive Measurement: Scanning without disturbing the grain, preserving quality.

- Real-Time Data Collection: Instantaneous measurement data for timely decision-making.

Integration with Management Systems

Automated measurement systems can be integrated with existing inventory and quality management systems, providing:

- Seamless Data Flow: Automatic synchronization of measurement data.

- Enhanced Monitoring: Real-time tracking of grain volumes and quality metrics.

- Data-Driven Decisions: Informed decision-making based on accurate, up-to-date information.

🌟 Benefits of Automated Volume Measurement in Grain Silos

Improved Accuracy and Efficiency

Automated systems reduce human error and increase measurement speed, leading to:

- Reliable Data: Trustworthy measurements for better planning and reporting.

- Operational Efficiency: Streamlined processes with reduced labor requirements.

Enhanced Inventory and Quality Management

With precise measurements, facilities can:

- Optimize Storage: Efficiently manage grain storage to prevent spoilage.

- Maintain Quality: Monitor and uphold grain quality standards throughout storage.

🏁 Conclusion

Adopting automated volume measurement systems in grain silos addresses the limitations of traditional methods, offering significant improvements in accuracy, efficiency, and integration with management systems. This technological advancement supports better inventory control, quality assurance, and overall operational effectiveness in grain storage facilities.