🏭 Project Background

A major cement producer relied on six belt conveyors to dispatch up to 13,300 tons of clinker per line daily. Traditionally, experienced staff manually controlled the loading process, but this outdated method caused:

- Material spillage due to human error.

- Labor inefficiencies during off-seasons with reduced demand.

- High management costs during peak seasons requiring 24/7 manual shifts.

🔍 The Vi LiDAR Solution: Automated Truck Volume Measurement

To address these challenges, Vi LiDAR deployed a fully automated truck volume measurement system. This intelligent solution integrates LiDAR scanners, license plate recognition, and smart cameras to ensure precise material loading with minimal human intervention.

⚙️ How It Works

1. License Plate Recognition

As the truck enters the loading zone, the system identifies the vehicle and initiates the measurement process.

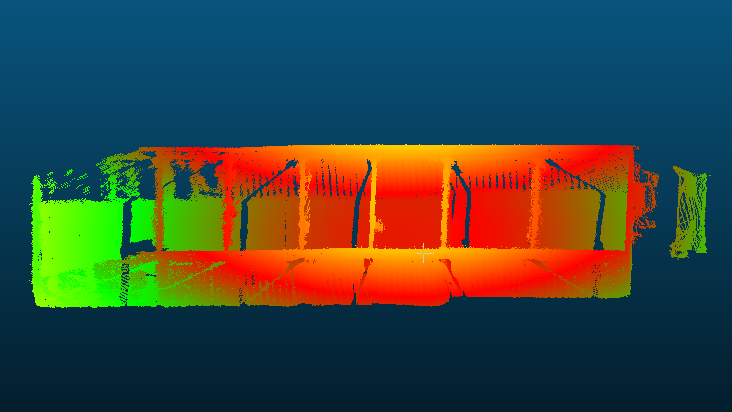

2. High-Precision LiDAR Scanning

Using high-resolution hybrid solid-state LiDAR, the system scans the truck bed to capture length, width, height, and volume.

3. AI-Based Load Calculation

Backend AI algorithms compute the optimal load volume and transmit the data to the automatic loading system.

4. Automated Loading

Once the truck enters the loading area, the system performs precise, contact-free loading, eliminating the need for manual control.

🔧 System Enhancements Based on Field Challenges

✅ Tarp Detection to Prevent Measurement Errors

Some trucks arrive with tarps still covering the bed. The system now automatically detects tarp coverage and notifies the driver to remove it before measurement.

✅ Adjustable Load Settings for Transport Safety

To prevent material overflow on long-distance routes, the system allows custom load settings based on route and safety requirements.

📈 Results & Business Impact

🚫 Unmanned, Automated Loading

- Drivers complete the loading independently.

- One manual position eliminated per shift.

- Flexibility to scale operations seasonally.

📊 Real-Time, Traceable Data

- Shipment data recorded and accessible via the cloud system.

- Improved material planning and inventory management.

🎯 Improved Accuracy, Less Waste

- No more material overflow due to overloading.

- Enhanced road safety and better resource utilization.

🧠 Conclusion

With the successful deployment of Vi LiDAR’s intelligent truck loading system, the cement manufacturer reduced costs, streamlined operations, and laid the foundation for a smarter, more automated future.

💬 “Vi LiDAR’s system eliminated the inefficiencies of manual loading. It’s precise, fast, and saves hours every day, making our logistics operations much more efficient.”

— Logistics Director, Cement Manufacturer