Industry Background

Global air freight volumes continue to surge at an average annual growth rate of 12%, intensifying operational pressures on airport cargo terminals. Critical challenges emerge particularly for volumetric (light bulk) cargo (items exceeding a 1:167 volume-to-weight ratio), where traditional manual measurement methods fail to meet modern requirements. A major international airport example highlights this issue: handling over 20,000 volumetric cargo items daily, manual measurements requiring 3-5 minutes per item caused inefficiencies, cargo backlogs, flight delays, and frequent customer complaints.

Key Industry Pain Points

Operational Inefficiency

- Manual processes reduced cargo flow speed by 40%

- Peak-hour backlog exceeded 6 hours

Dispute Risks

- 15% of cargo faced disputes due to incomplete/inaccurate data

- Annual dispute resolution costs reached $500,000

Management Blind Spots

- Lack of digital records hindered root-cause analysis

- Increased compliance risks for non-compliant cargo

AI-Powered Volume Measurement Solution

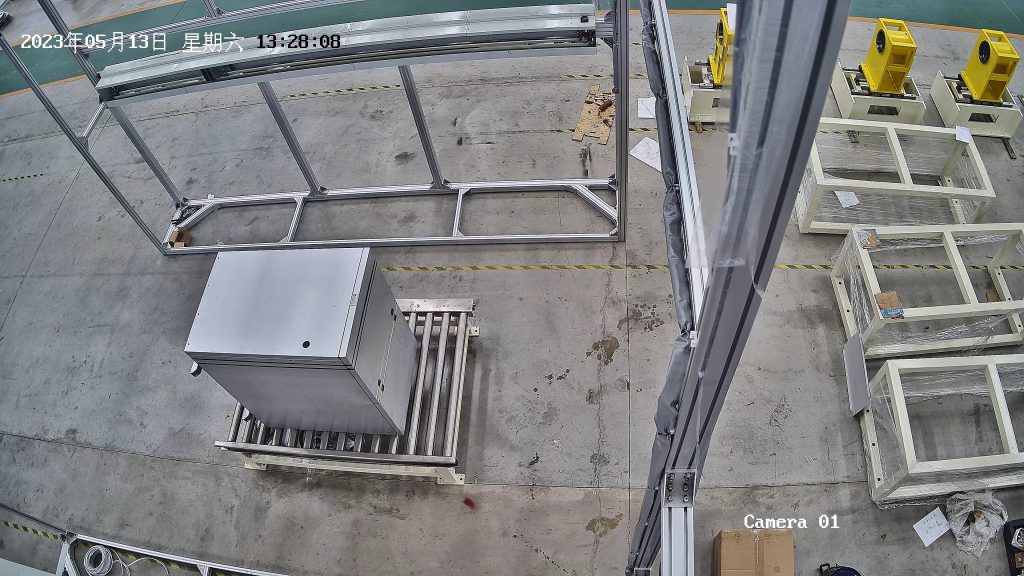

Shanwei Technology introduces an Intelligent Air Cargo Dimensioning System, integrating 3D vision and dynamic measurement technologies to automate cargo management from entry to loading.

Core Technical Architecture

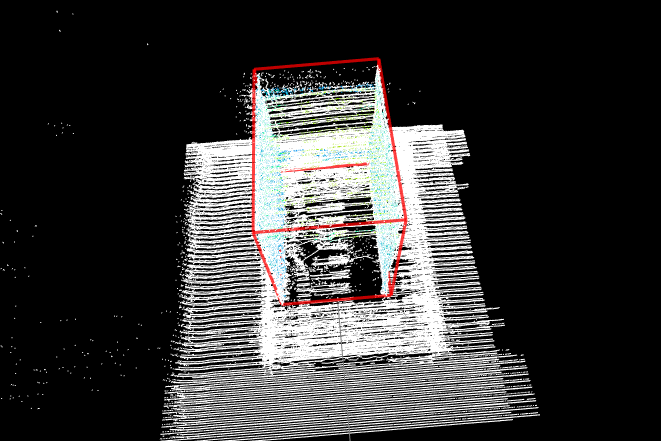

Dynamic Volume Measurement Module

- Equipped with multi-line LiDAR and high-frame-rate industrial cameras (15 scans/sec)

- Point cloud stitching algorithm ensures millimeter-level accuracy (±1cm error) in motion states

- Supports large cargo up to 3.5m × 3.5m × 8m

Smart Image Tracing System

- Generates 6-sided HD images (4096×2160 resolution) per cargo

- Data package includes:

- Volume metrics

- Density estimation

- 360° visual documentation

- Timestamps and conveyor coordinates

Airport-Specific Adaptations

- Vibration-resistant mounts eliminate conveyor belt interference

- Low-light compensation maintains >95% recognition in dark environments

- IATA data interface enables seamless integration with cargo settlement systems

Competitive Advantages & Value Proposition

Technical Leadership

| Feature | Specification |

|---|---|

| Scanning Frequency | 50Hz with sub-millimeter point cloud |

| Processing Speed | 8 seconds/item (vs 5 minutes manually) |

| Throughput Increase | 37x improvement |

Operational Benefits

- Dispute Resolution: 90% faster resolutions, $800K annual savings

- System Integration:

- CargoXML/CARGO-IMP protocol support

- Direct billing data interface to airline systems (zero-error)

- Reliability:

- 24/7 operation with IP65-rated protection

- Self-cleaning optics reduce maintenance costs by 62%

- <15-minute fault response time

Implementation Results

Deployed at a major hub airport:

- Throughput: Daily capacity surged from 21,000 to 48,000 items

- Cost Optimization: Reduced 45 measurement staff, saving $2.7M annually

- Traceability: Anomaly resolution cut from 2 hours to 3 minutes

- Customer Satisfaction:

- 92% dispute reduction

- IATA Innovation Certification

“This system elevated our light cargo handling to industry leadership. Even during ‘Double Eleven’ peaks, cargo met same-day loading requirements with record-low complaints.”

— Cargo Operations Director, Major International Airport

Technical Specifications

| Parameter | Specification |

|---|---|

| Measurement Accuracy | ±1cm (dynamic)/±0.5cm (static) |

| Max Scanning Speed | 2m/s |

| Minimum Cargo Size | 20cm × 20cm × 10cm |

| Data Retention | Cloud permanent + 90-day local |

| Environmental Range | -20°C to 55°C, 10-95% RH |

Shaping the Future of Air Cargo

Through dynamic measurement, visual traceability, and deep aviation system integration, Shanwei’s DWS solutions are defining a new era of intelligent logistics. This technological breakthrough delivers measurable ROI while addressing critical industry challenges, positioning adopting airports at the forefront of global cargo innovation.