Automated Volume Measurement for Freight Handling at Scale

📦 Customer Background

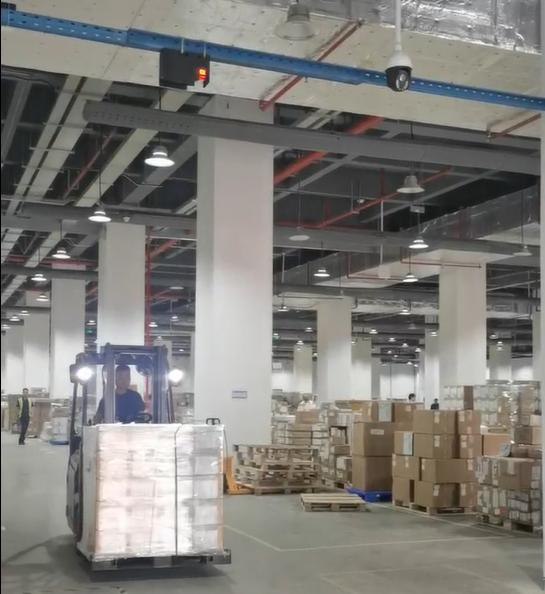

Our client is a logistics company specializing in freight handling for large-scale manufacturing clients such as Lenovo. Every day, they manage the inbound registration of goods for over 100 trucks. Under traditional workflows, each shipment had to be manually inspected, scanned, and its volume manually measured before entering the system for freight cost calculation.

This manual process was inefficient and prone to error, limiting logistics speed and transparency.

🔍 Challenges

1. Low Measurement Efficiency

Manual scanning and volume measurements were time-consuming, significantly slowing down the inbound process.

2. Poor Accuracy, Leading to Billing Disputes

Human error in volume measurement often resulted in incorrect freight charges, damaging client trust and requiring frequent corrections.

3. High Labor Dependency

Operators had to be on constant standby to conduct manual checks. Missing a delivery window meant physically locating goods in the warehouse, further reducing efficiency.

🚀 The VI LiDAR Solution: VI-VMS-L

To address these pain points, VI LiDAR implemented the VI-VMS-L system — an automated, high-precision volume measurement solution. Using advanced LiDAR sensors and real-time processing, the system captures volume data without stopping operations and integrates directly with the client’s ERP/WMS system.

✅ Key Advantages

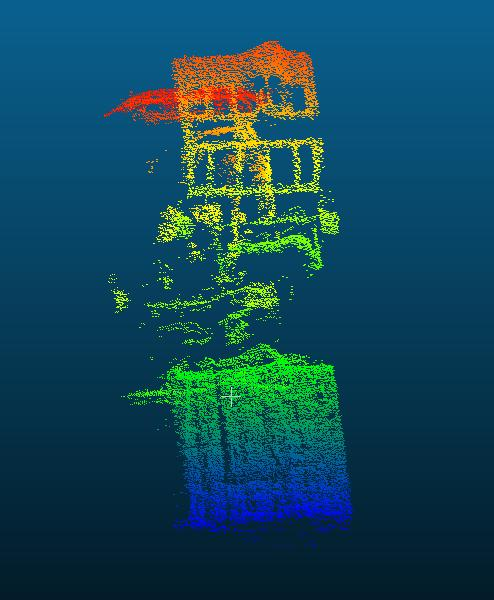

🔹 High-Precision Measurement (±2% Accuracy)

Powered by industrial-grade laser scanners, the system ensures over 98% accuracy in volume measurements — suitable for billing and compliance use.

🔹 Dynamic Drive-Through Measurement (≤5 km/h)

No need to stop. Goods can pass through the measurement area at speeds up to 5 km/h, and the system will automatically generate volume data.

🔹 Intelligent Anti-Interference Algorithm

Custom-developed algorithms for logistics environments can intelligently detect and eliminate plastic wrap interference, ensuring precise and reliable measurements even with transparent film.

📈 Implementation Results

- 3× Faster Inbound Efficiency

Automated scanning + ERP integration significantly reduces manual data entry. - 80% Reduction in Measurement Error

Accurate volume data minimizes billing disputes and enhances client satisfaction. - 50% Labor Cost Savings

Unattended measurement eliminates the need for round-the-clock staff supervision.

🗣️ Client Testimonial

“The VI LiDAR system has completely eliminated the inefficiencies of manual volume measurement. It’s accurate, fast, and saves us hours of processing time every day. Our overall logistics performance has improved dramatically.”

— Logistics Manager, [Hichen Logistics]