Client Overview

The client is a premium ceramic manufacturer known for producing high-quality porcelain products. To meet the requirements of different formulations, the factory must prepare and manage a wide variety of clay-based raw materials.

Challenges

- Each ceramic product requires specific types of raw clay. Managing diverse raw materials in large volumes poses a significant logistical and quality control challenge.

- Prolonged storage leads to material compaction and moisture absorption, which degrades sintering performance and results in visual defects like black spots in finished porcelain.

- The raw materials are sourced from various regions across China. Relying on order-based procurement increases delivery time and significantly raises transportation costs.

ViLiDAR’s Tailored Solution

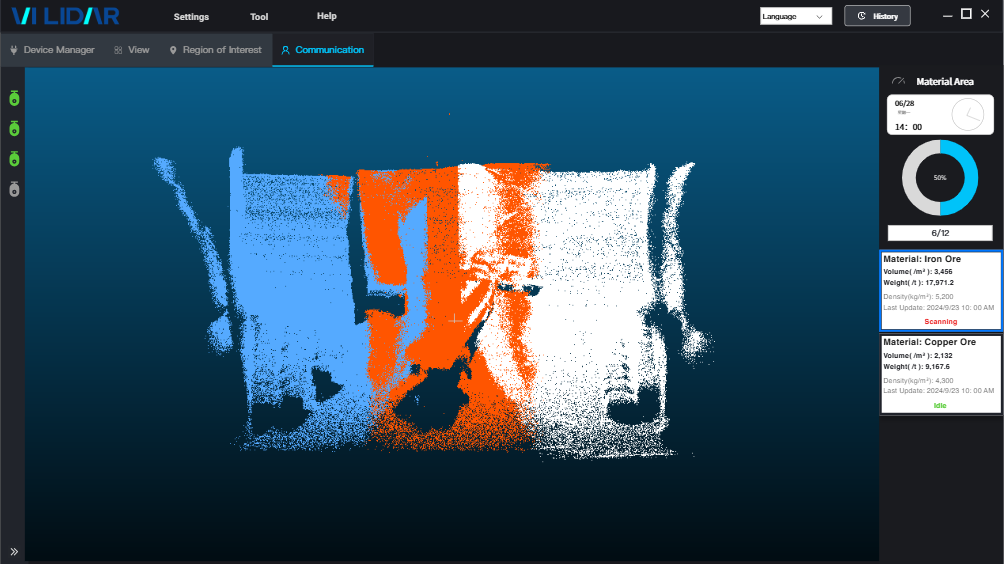

ViLiDAR provided a customized 2D LiDAR + PTZ platform solution to monitor and manage stockpile volumes of raw materials in real time. The system delivers non-contact, automated volume scanning designed for dusty, semi-open warehouse environments.

Key Features of the System

1. Modular Design for Multi-Zone Warehouses

Six ViLiDAR volume scanning units were installed across the warehouse. The modular design enables flexible deployment across different types of storage environments, whether indoor or outdoor.

2. Automatic Lens Cleaning

Dust is a major issue in material stockpiles and can reduce LiDAR performance over time. Each ViLiDAR unit includes an automated lens cleaning mechanism to ensure long-term accuracy and low maintenance in harsh environments.

3. Material-Specific Volume Calculation

The system allows the user to custom-define different material zones within the warehouse. ViLiDAR automatically calculates and visualizes the volume of each designated area, giving the team instant insight into raw material availability.

Implementation Results

- Improved visibility of raw material usage and replenishment needs

- Reduced transportation cost by 18% through smarter procurement planning

- Enhanced material quality management, reducing product defects by 15%

- Enabled sales and production teams to make faster, data-driven decisions

Client Testimonial

“Thanks to ViLiDAR, we’ve finally turned our warehouse into a measurable and manageable asset. Our inventory data is now live, reliable, and easily accessible.”

— Production Manager, Ceramic Manufacturing Group