Vi-LiDAR

In construction material handling, sand/gravel mining, coal mining, and similar operations, accurately measuring load volumes is a critical task. It not only affects production efficiency and cost control but also directly impacts resource utilization and environmental protection. However, accurate Measure Bulk Material Volumes (e.g., sand, stone, coal) is extremely challenging—traditional methods often suffer from large errors and low efficiency. With technological advancements, the application of Lidar Volume Measurement Systems has provided a new solution to this problem.

I. The Extreme Difficulty of Measuring Bulk Material Volumes

Bulk materials, such as sand, stone, and coal, have complex physical properties (e.g., particle shape, size, density, and stacking patterns) that make volume measurement highly complicated. During stacking, bulk materials form irregular shapes that cannot be easily described using simple geometric models. Additionally, the density distribution of bulk materials is often uneven—density differences between different parts can lead to measurement errors. Moreover, bulk materials may shift or deform during loading/unloading, further increasing measurement difficulty. Thus, accurately and quickly measuring bulk material volumes has long been a challenge in construction and mining operations.

II. Traditional Methods: Large Errors and Low Efficiency

Traditionally, two main methods are used to measure bulk material volumes: manual measurement and mechanical measurement.

- Manual measurement: Workers use tools like rulers or tape measures to manually measure dimensions (e.g., length, width, height) and calculate volume. This method is time-consuming, labor-intensive, and prone to human error—measurement accuracy is heavily influenced by operator skill.

- Mechanical measurement: Loaders or excavators are used to load materials, and volume is estimated based on the bucket capacity of the equipment. However, this method also has flaws: bucket capacity can change over time due to wear, deformation, or improper use, leading to inaccurate estimates. Additionally, traditional methods are inefficient—especially in large-scale, high-intensity operations, manual and mechanical measurements cannot meet production demands.

III. Lidar Measure Bulk Material Volumes Systems: Accurate, Efficient, and Convenient

A Lidar Volume Measurement System is an automated measurement system based on laser ranging principles. It uses laser beams to scan bulk materials, calculating volume by analyzing the reflection time and angle of the laser beams. This system offers significant advantages in solving bulk material volume measurement challenges:

1. High-Precision Measurement

Lidar systems emit and receive laser beams rapidly, collecting large amounts of data in a short time. The short wavelength and concentrated energy of laser beams allow them to penetrate tiny gaps on the surface of bulk materials, capturing more accurate volume information. As a result, Lidar systems achieve high-precision measurements with extremely low error rates.

2. Fast Measurement Speed ,( Measure Bulk Material Volumes )

Lidar beams scan quickly, completing a full scan of a bulk material pile in minutes. The system also supports automated measurement, eliminating the need for manual intervention and greatly improving efficiency. In large construction sites, Lidar systems can monitor and record load volumes in real time, providing strong data support for production scheduling and cost control.

3. Wide Application Prospects

Lidar Volume Measurement Systems are not limited to construction material handling, sand/gravel mining, or coal mining—they can also be used in logistics warehousing, port loading/unloading, and other fields. With the development of IoT technology, Lidar systems can be integrated with IoT platforms to enable remote monitoring and intelligent management of load volumes, further improving production efficiency and resource utilization.

4. System Components and Operation

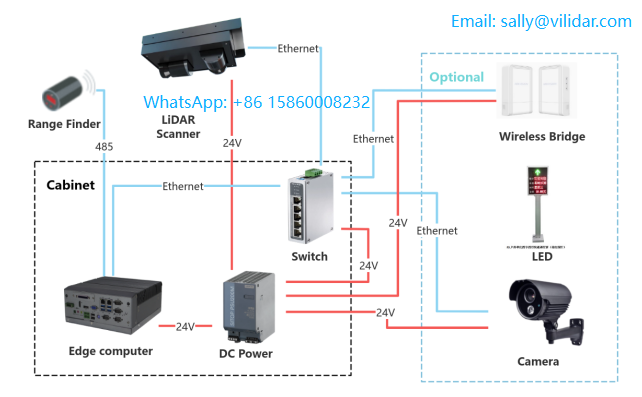

A typical Lidar Volume Measurement System consists of four parts: laser transmitter, receiver, data processing unit, and display terminal. The laser transmitter emits laser beams to scan the bulk material; the receiver captures the reflected beams and converts them into electrical signals; the data processing unit analyzes the signals to calculate volume; and the display terminal shows measurement results and relevant information. The system of “Measure Bulk Material Volumes ” is simple in structure, easy to operate, and suitable for various working environments.

Conclusion

Lidar Volume Measurement Systems offer significant advantages in measuring bulk material volumes for construction material handling, sand/gravel mining, coal mining, and other operations. They enable high-precision, efficient, and convenient measurements, providing strong data support for production scheduling and cost control. Lidar-based intelligent systems are widely used in mine truck transportation, earthwork transportation, warehouse stack management, and other fields.