JF Earthwork Company is located in Putian, Fujian, China, and is a long-term operator of Earthwork services. The company owns over 70 Earthwork trucks and needs to transport hundreds of trips of Earthwork materials daily. By adopting the VI-LIDAR VI-TVMS-D (Vi-Truck Volume Measurement Scanner-D) 3D scanning ( volume scanning ) technology, JF Company has achieved significant improvements in operational efficiency, data accuracy, and customer trust.

General Manager Wang Lei of the company detailed how VI-LIDAR’s VI-TVMS-D was successfully integrated into daily operations, boosting logistics efficiency, optimizing load measurement, streamlining back-end data management processes, and significantly reducing disputes with clients.

In the Earthwork industry, the traditional “per-vehicle billing” model remains a persistent challenge. Diverse vehicle types, human error, and payment disputes form three major obstacles, trapping companies in a dual crisis of efficiency and trust. General Manager Wang Lei reflects: “We dispatch over 70 dump trucks daily for hundreds of round trips, yet contracts are signed with only vehicle-based volume estimates. This blind contracting approach often leaves us either footing the losses or facing client accusations of cutting corners.”

Challenge: Inconsistent load measurement and low operational efficiency

Prior to integrating the VI-TVMS-D system with VI-LIDAR into its operational framework, JF Earthwork Company encountered three primary challenges:

- Inconsistent load measurement data;

- Manual measurement proved time-consuming and labor-intensive due to varying vehicle models;

- Significant discrepancies between the actual transported volume and manually calculated quantities, compounded by inaccurate billing from the bulk procurement of earth materials.

General Manager Wang Lei outlined the issues with the outdated system:

We estimate the amount of material per truck based on its size and the quantity of vehicles it hauls, aiming to maintain a consistent load of around a certain number of scoops each time.

This estimation method relies entirely on the subjective judgment of excavator and loader operators. Take excavators as an example: while a fixed bucket capacity is commonly assumed, actual operations often show deviations due to factors like material type, compaction level, truck dimensions, and bucket wear. This results in discrepancies between actual loading volumes and declared data, causing inefficiency and billing inconsistencies. Additionally, some drivers open the tailgate, damaging the rear panel and preventing full truck loading. Such practices also make it difficult to ensure fair compensation settlement.

Solution: VI-TVMS-D volume scanning technology of VI-LIDAR

To address these challenges, JF Earthwork company partnered with VI-LIDAR , which delivered a cutting-edge solution powered by its Load Volume Scanning technology.

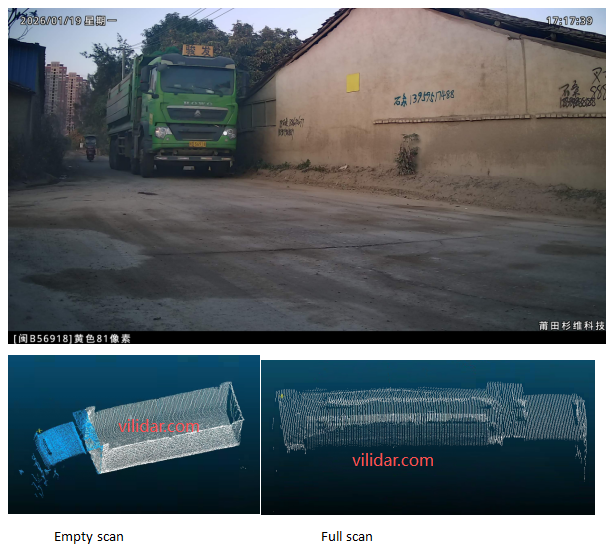

The VI-TVMS-D’s system employs laser scanning technology to precisely measure the volume of internal materials as trucks pass through the scanner, delivering accurate and stable data. This solution ensures real-time, precise tracking of each shipment, significantly reducing human errors and enhancing overall transport efficiency.

Manager Wang Lei explained the decision to adopt the VI-LiDAR system:

We ultimately chose the VI-LiDAR system, which completely resolved all our concerns. It not only provides real-time visibility of truck loading status but also accurately records license plate numbers and transportation routes. This system streamlines cargo calculation and tracking, while enabling real-time monitoring of goods movement metrics at the operational site.“

The integration of VI-LiDAR’s VI-TVMS-D system has enabled JF Earthwork Company to completely eliminate operational uncertainties. By automatically measuring and recording each truck’s precise cargo load, the company now relies on hard data to enhance logistics efficiency and billing accuracy, while also preventing disputes between buyers and sellers.

Improve operational efficiency

The VI-TVMS-D system, powered by VI-LiDAR, has dramatically boosted operational efficiency at JF earchmoving company. The company now maintains precise tracking of material transportation volumes.

The deployment of each truck has effectively reduced unnecessary transport trips and optimized loading procedures. Before implementing the VI-LiDAR system, truck loading volumes were frequently under-or overloaded due to rough estimates. Now, every truck achieves efficient loading.

Manager Wang Lei explained how this technology enhances speed and accuracy:

Even truck drivers are pleased with this change, as they are mostly charged based on the actual volume combined with the number of vehicles transported. Previously, when invoicing, drivers would notice that some vehicle models varied in size, resulting in less noticeable differences in load capacity, which was unfair. Now, with the VI-LiDAR system, there’s no need for estimation—they have a clear understanding of the numbers.

This precision means more stable truck loading, reducing downtime and improving efficiency, as trucks no longer need to return to the site to adjust for underloading or overloading.

Simplify billing and data management

VI-TVMS-D, powered by VI-LiDAR, not only boosts operational efficiency but also significantly optimizes backend data management for JF Earthworks. The system generates daily reports that meticulously track both the number of trucks scanned and the total volume of materials transported. These reports provide invaluable data support for the company’s billing department.

Manager Wang Lei elaborated on how the system impacts the company’s billing process:

We retrieve reports from the system daily to accurately track on-site operations, including the number of trucks entering/leaving and the volume (volume or weight) of goods transported. Based on this data, we generate invoices for the finance department.

VI-LiDAR reduces the risk of errors in manual data entry by automating data collection and reporting processes. This streamlines the invoice workflow, ensuring customers are billed accurately based on actual material shipments rather than relying on estimated figures.

Furthermore, the VI-LiDAR’s VI-TVMS-D system supports remote monitoring. If load measurement anomalies or deviations occur, the team can remotely access the system for troubleshooting and handling.

General Manager Wang Lei emphasized the advantages of remote access, stating:

This device is highly practical when enabling remote access and real-time scanner status monitoring. In case of a malfunction, the remote access feature can provide significant assistance.

This remote monitoring capability enhances regulatory efficiency, enabling JF Earthworks to swiftly address emergencies without requiring on-site presence.

Strengthen Customer Relationship with Accurate Data

VI-LiDAR not only streamlines internal workflows but also significantly enhances the relationship between the company and its clients. Customers can now be confident that the volume measurements of materials listed on their bills are accurate and reliable. Unlike the outdated estimation system, the VI-TVMS system delivers precise and trustworthy data for clients.

This transparency not only strengthens trust but also gives JF Earthworks a competitive edge in the market. Customers appreciate the clarity provided by VI-LiDAR, knowing their bills are based on precise measurements rather than estimates.

The Future of Vi-LIDAR

Vi-LIDAR has had a highly positive impact on JF Earthworks, significantly boosting operational efficiency, data accuracy, and customer relationships. With this technology, JF Earthworks can now track each cargo load in real time, generate precise billing reports, and ensure trucks are fully loaded.