Project Overview

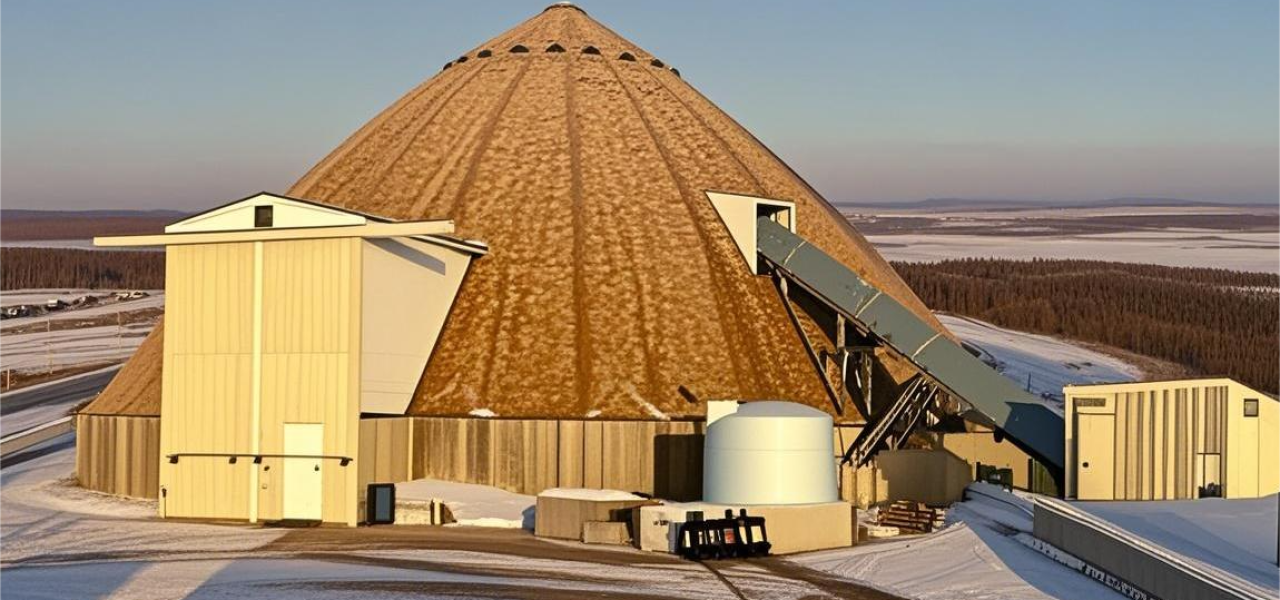

In North America, government agencies stockpile de-icing salt (rock salt) during spring and summer to ensure road safety in winter. However, excessive salt storage increases operational costs and prolonged storage can lead to salt clumping, damaging spreading equipment. Lakes District Maintenance previously relied on manual visual inspections for salt inventory, which were inefficient and prone to errors. To address these challenges, ViLiDAR provided a solution utilizing LiDAR and point cloud image fusion technology for precise, automated salt stockpile monitoring, enhancing inventory management and operational efficiency.

Background

Lakes District Maintenance is responsible for road de-icing operations in a specific North American region, managing multiple salt storage facilities annually. Traditional monitoring methods presented several issues:

Imprecise Storage Management: Lack of real-time data on salt pile heights resulted in resource wastage and equipment damage.

Inaccurate Visual Estimates: Manual measurements couldn’t accurately determine salt pile volumes, leading to overstocking or shortages.

Labor-Intensive Inspections: Engineers had to travel between salt yards, consuming significant time and manpower.

ViLiDAR’s Salt Stockpile Volume Measurement Solution

To tackle these issues, ViLiDAR implemented an intelligent measurement solution combining LiDAR and image fusion for efficient and precise salt pile monitoring.

Key Features

- Adaptive Scanning Approach:

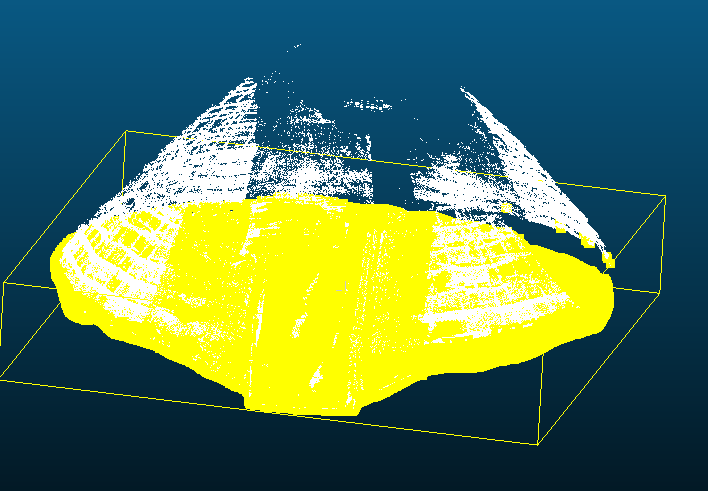

- Automatically adjusts scanning modes based on salt yard geometry (dome, open-air, trapezoidal), completing 3D modeling of 2,000㎡ salt piles within 5 minutes.

- Intelligent Obstacle Detection:

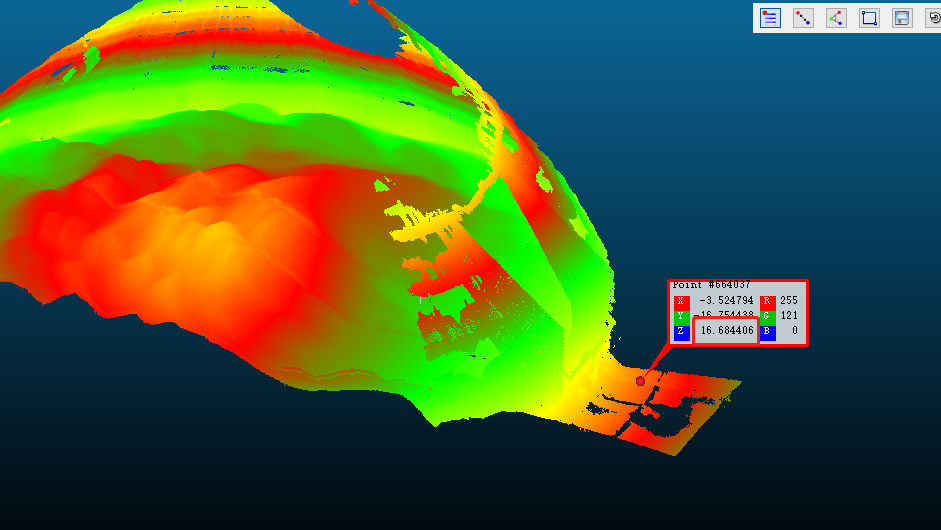

- AI algorithms exclude dynamic objects like loading equipment from measurements, achieving a salt volume measurement error margin of ≤2.3%.

- Real-Time Monitoring & Data Integration:

- Edge computing nodes refresh data every 10 minutes, merging LiDAR point clouds with visible light images to generate textured 3D salt pile models.

- GIS mapping labels each yard’s salt volume and transportation distances, optimizing winter salt truck dispatch routes.

Salt stockpile Volume management system Outcomes

ViLiDAR’s salt pile measurement solution enabled Lakes District Maintenance to achieve precise inventory management and efficient operations, resulting in:

- Accurate Reserves: Salt volume estimation errors reduced from 35% to 2.5%, eliminating winter salt shortages.

- Labor Savings: Reduced salt yard inspection manpower by 82%, enhancing response speed during extreme weather by 5 times.

- Cost Reduction: Annual salt wastage decreased by $470,000, and equipment maintenance costs dropped by 68%.

Client Testimonial

“This winter, I no longer had to shuttle between salt yards.”

— Michael, Engineer at Lakes District Maintenance