Customer Case Study – 3D Vision Guidance System for Overhead Crane

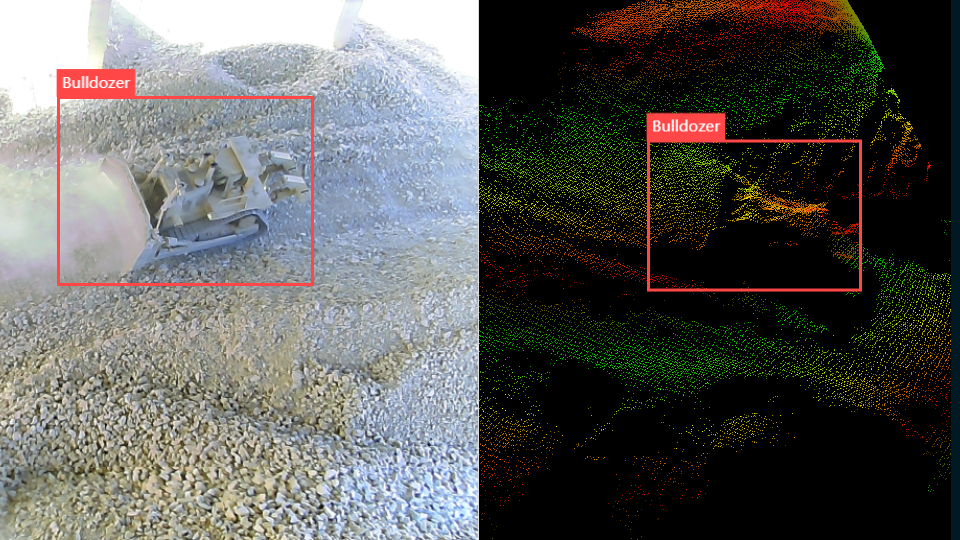

A sulfur trading company faced critical safety and efficiency challenges in managing large volumes of sulfur granules. Sulfur dust, fire hazards, and inefficient manual crane operations reduced space utilization and raised compliance risks. VI LiDAR deployed a 3D Stockpile Scanning System, integrating LiDAR scanners with overhead cranes to build real-time 3D models of stockpiles and generate automated stacking and reclaiming strategies. The solution enabled smart navigation, minimized worker exposure to hazards, improved space utilization, reduced labor costs, and ensured compliance with environmental standards. VI LiDAR is helping sulfur enterprises build safer, smarter, and greener warehouses.

Customer Case Study – 3D Vision Guidance System for Overhead Crane Read More »